A Leader in the CSTD

Market for a Reason

Our state-of-the-art products are both a design and engineering feat – with our pressure equalization technology fueling everything we do.

About EQUASHIELD

EQUASHIELD

Product Portfolio

EQUASHIELD® is the most advanced Closed System Transfer Device (CSTD) available. It has been recognized as the fastest and most user-friendly system in numerous peer-reviewed studies.

EQUASHIELD’s Mundus Mini HD revolutionizes hazardous drug compounding with advanced automation for enhanced safety, quality, and efficiency. By utilizing EQUASHIELD’s CSTDs, it reduces contamination, exposure, and errors, ensuring smarter and safer compounding.

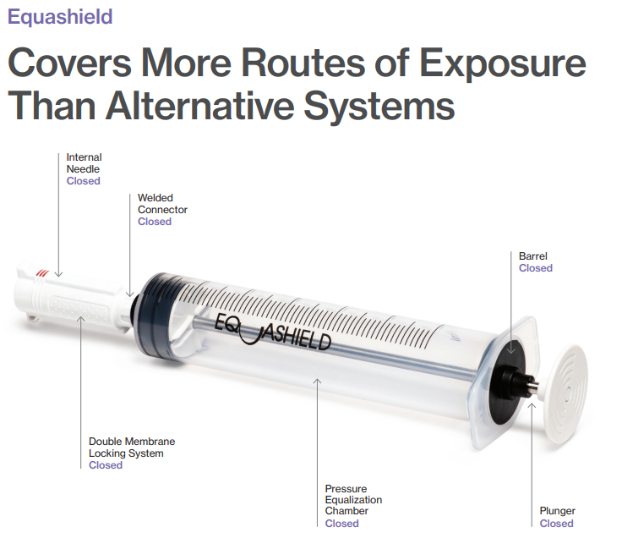

Healthcare professionals prefer EQUASHIELD for several reasons. Firstly, its closed back system offers more coverage of routes of exposure compared to alternative systems. Secondly, EQUASHIELD is the fastest and easiest system, requiring the fewest steps and least time in numerous peer-reviewed studies. These two factors make EQUASHIELD the safest and most most user friendly choice on the market today.

Unleash the Power of Automation

Mundus Mini HD significantly reduces the risk of errors attributable to the compounding process. By integrating embedded cameras, machine vision, and AI, it provides enhanced traceability, reporting, and verification of dose accuracy.

The Mundus Mini HD supercharges your efficiency, delivering up to an impressive 37 individual doses per hour and meeting your compounding needs while saving valuable labor resources.

- Streamlined

workflow - EMR

integration - Based on

CSTD system - High

throughput

How can EQUASHIELD CSTDs help?

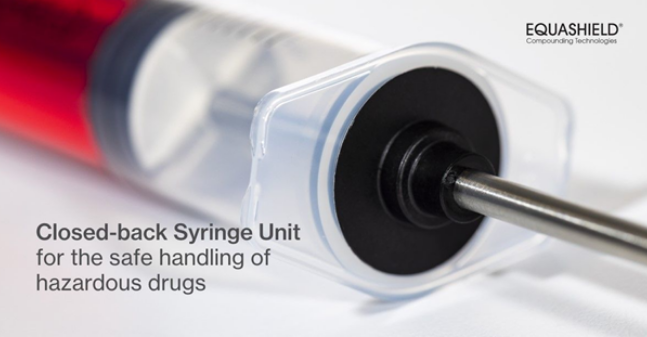

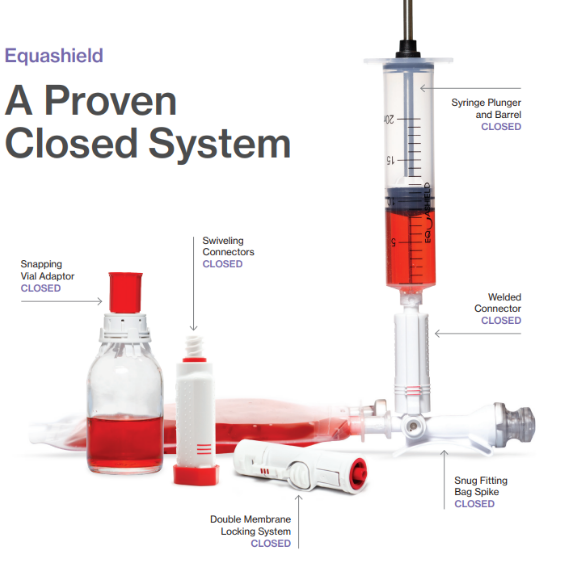

The EQUASHIELD system is the only closed system on the market. It effectively prevents syringe plunger contamination and accidental disconnection.

Pharmacists can protect themselves from hazardous drug exposure by implementing various safety measures, including the use of EQUASHIELD® Closed System Transfer Devices (CSTD). These devices are designed to create a physical barrier between the clinician and the hazardous drug, minimizing the risk of exposure during the compounding and administration process.

EQUASHIELD® CSTDs are unique in their ability to cover more routes of exposure than other solutions. Extensive clinical evaluation and studies4 have shown that standard syringes can become contaminated with hazardous drugs on surfaces exposed to the environment, potentially leading to vapor escape and plunger contamination. EQUASHIELD® addresses this issue with its closed-back syringe design, providing superior protection compared to alternative systems.

In conclusion, minimizing exposure to hazardous drugs is crucial for the long-term health and safety of medical personnel. By implementing best practices, using CTDS, appropriate PPE and equipment, and providing ongoing training and support, medical facilities can create a safer work environment for all staff members involved in handling hazardous drugs.

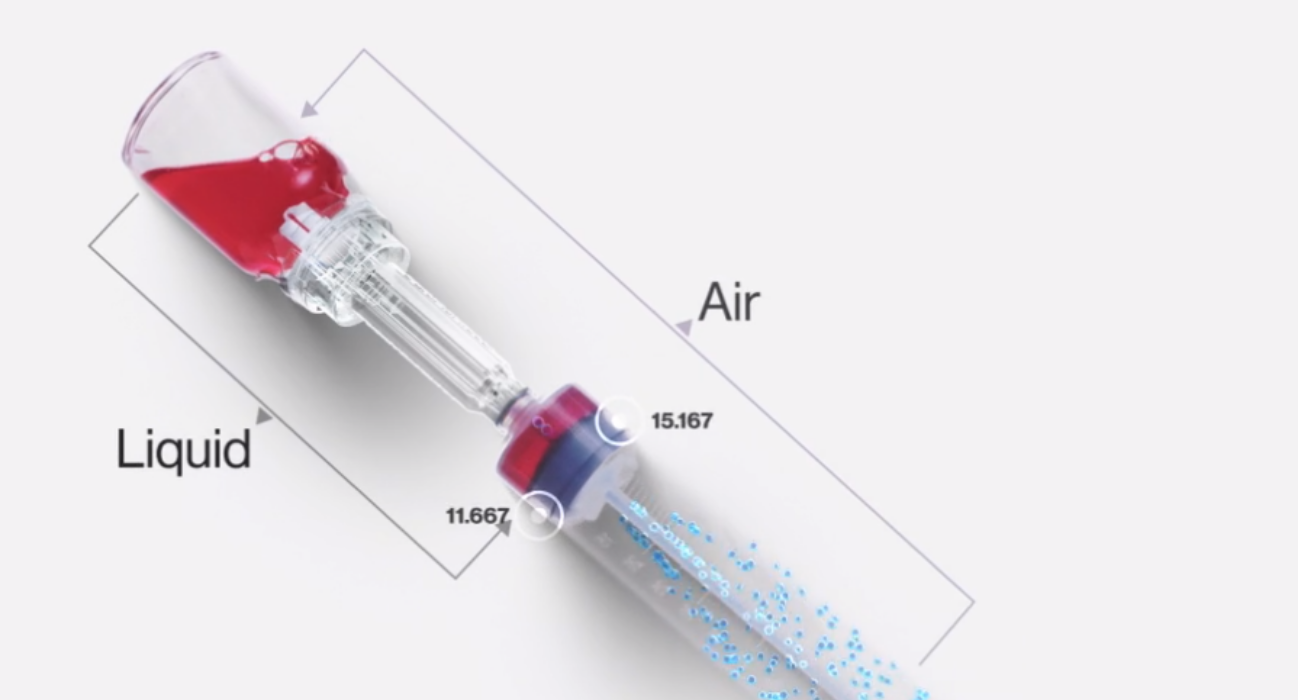

Unlike standard syringes, which are prone to contamination with each use and can lead to hazardous drug spills if the plunger is accidentally removed, EQUASHIELD ensures the containment of hazardous drugs and vapors. It achieves this through a unique encapsulated syringe design, featuring an internal sterile air chamber and a closed pressure equalization system.

How it works

Back of a Syringe Unit with laser

Superior Safety & Ease of Use

EQUASHIELD adheres to all NIOSH protocols and definitions of a CSTD, as well as USP <800>, FDA ONB, ISOPP, and ONS guidelines. With its welded connection point, it comes as a fully assembled, ready-to-use syringe unit, preventing disconnection of the syringe connector. Needlesafe technology provides complete needle encapsulation and dry disconnection membranes, effectively eliminating exposure to HD residue, needle sticks, and preventing microbial ingress for up to 7 days.

The unparalleled safety features and ease of use make EQUASHIELD the best choice for healthcare professionals seeking top of the line protection against hazardous drug exposure.